Company news

News information

"Customer First, Innovation Driven, Quality Assurance, and Unity of Knowledge and Action" are the core values that Blue Solid people have always practiced. In the third year of the company's establishment, we launched "Standing Strong at 3: Blue Solid Cultural Role Model Interviews," which tells the stories of employees' growth with the company through text and images. Among them, some have personally participated in the construction of the factory buildings, some have witnessed the birth of new products, some have worked hard on the front lines of production, and others have silently contributed in service positions... No matter what roles they play, they are all striving together with the company, shining brightly in their third year!

Blue Solid No.10

In 2021, the booming new energy industry attracted countless people's attention, and Zou Kui was one of them. "At that time, our company had just been established and was actively recruiting. Based on my understanding of lithium batteries, I firmly believed that solid-state batteries would be the inevitable trend for the next generation of lithium batteries. So, I submitted my resume and successfully passed the interview, becoming the company's 10th employee. I felt very honored to join the company at such an early stage of its development," Zou Kui said, reminiscing about the scene at that time.

Quality = Lifeline

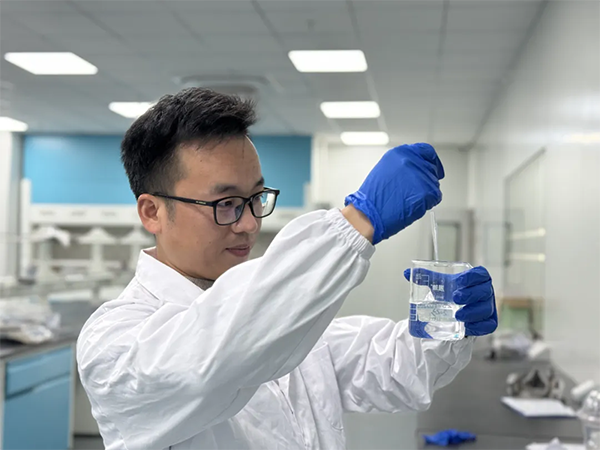

Research and development engineers follow strict quality standards and norms when developing products to ensure that the safety and reliability of the products meet or even exceed industry requirements. By conducting in-depth research on materials and processes, they continuously optimize formulas and carry out ongoing experimental validations to identify and resolve potential quality issues, thereby ensuring the reliability of the final product. Zou Kui believes, "In the new energy automotive industry, power batteries involve many complex chemical and electrochemical reactions. A minor non-compliance in material specifications could trigger a chain reaction, causing significant safety issues. Quality assurance is the lifeline of the entire industry chain and is of utmost importance."

Quality-Driven Breakthroughs

Once, Zou Kui's R&D team received a customer's request for the development of solid-state electrolyte oil-based slurry samples with strict moisture control requirements. Despite the company's limited conditions at the time (without its own dry room), Zou Kui and his colleagues still tried their best to optimize the preparation process. However, the moisture content of the final samples was still far higher than the customer's requirements. "After coordinating with multiple parties, we finally obtained the opportunity to use a dry room in a unit within the park. We immediately began experiments on that day. Although the initial results were still not satisfactory, with the guidance of our leaders, we identified the issue and improved our methods. We successfully prepared the samples that met the requirements and completed the delivery," Zou Kui said. In a short time afterward, Zou Kui and other engineers also explored moisture control methods without a dry room and successfully reduced the moisture content to a low level.

Staying True to Blue

As a veteran employee, Zou Kui has witnessed the rapid development and gradual perfection of Blue Solid New Energy. "I will continue to practice Blue Solid's core values and contribute my part to the company's vision of becoming a world-class new energy material enterprise. At the same time, I hope the company will continue to grow steadily and become better and better!"